Things that keep me up at night: Part 2

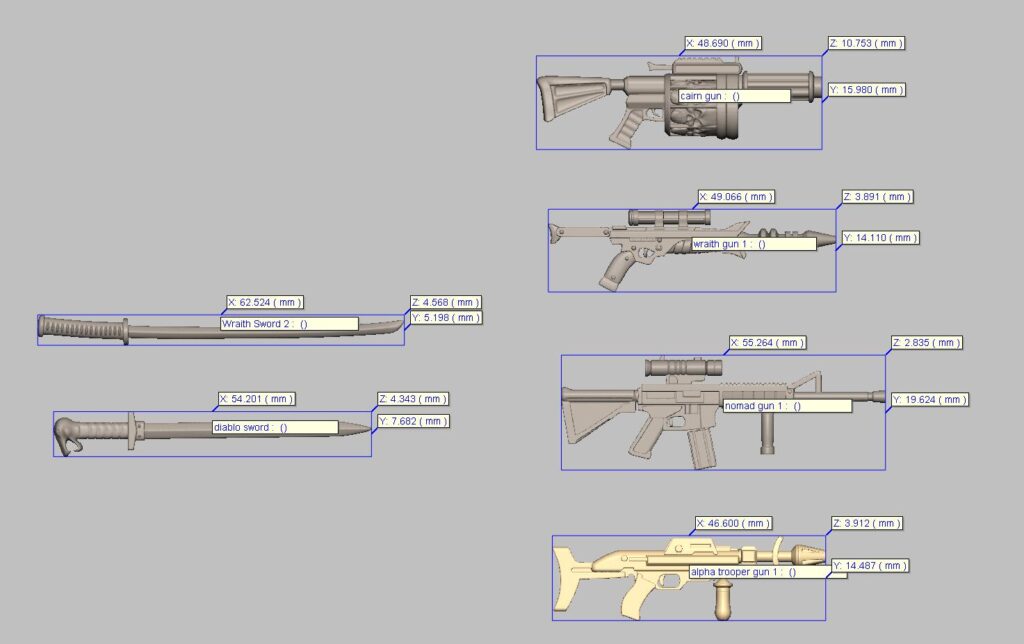

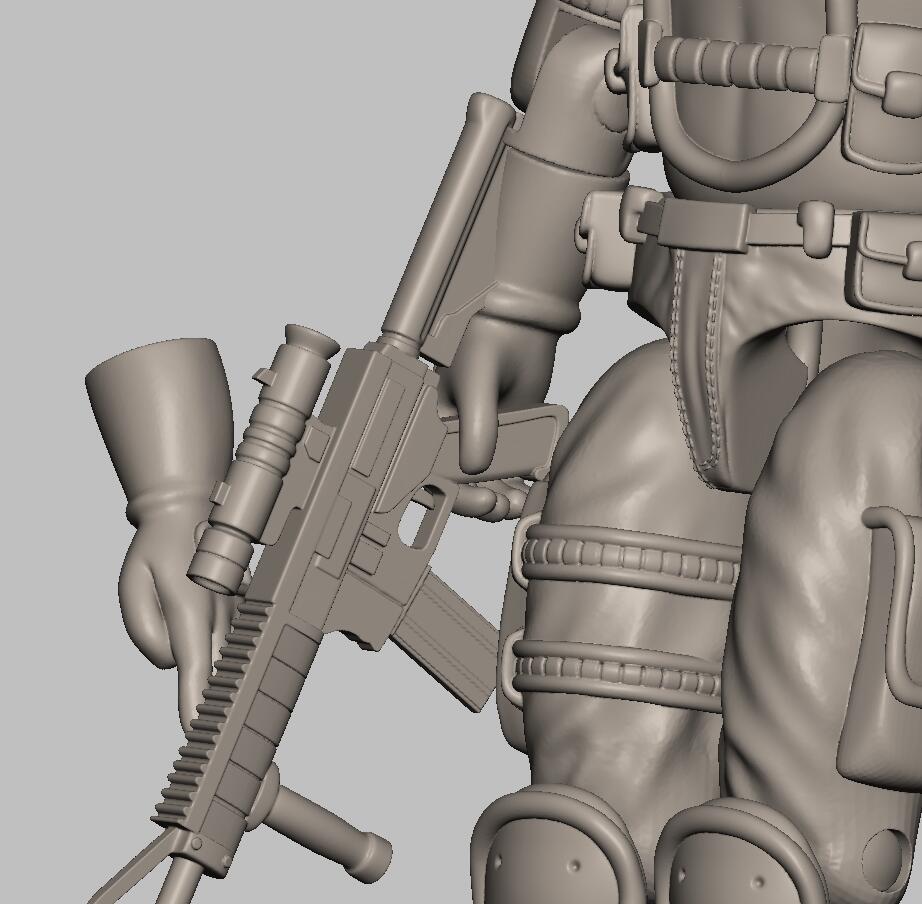

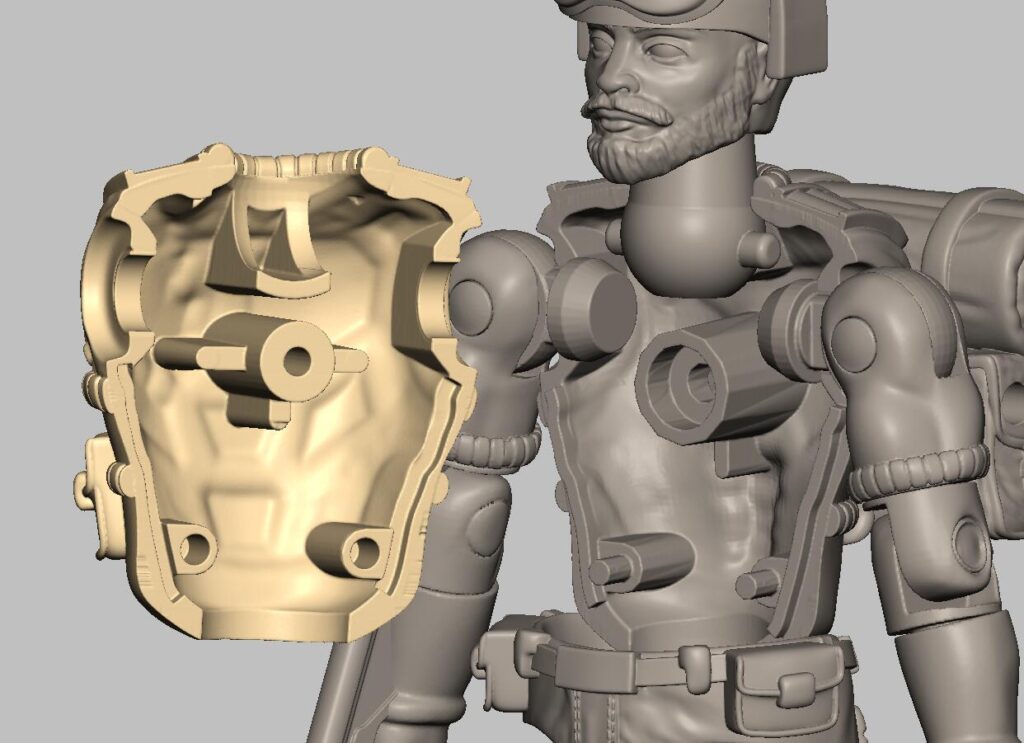

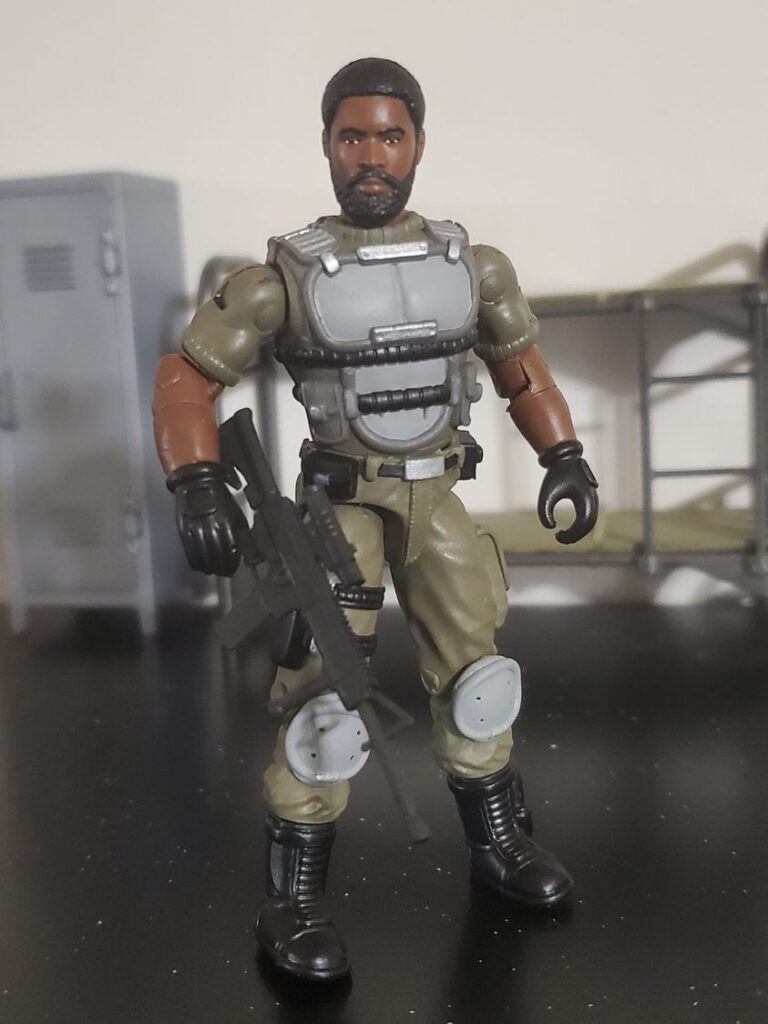

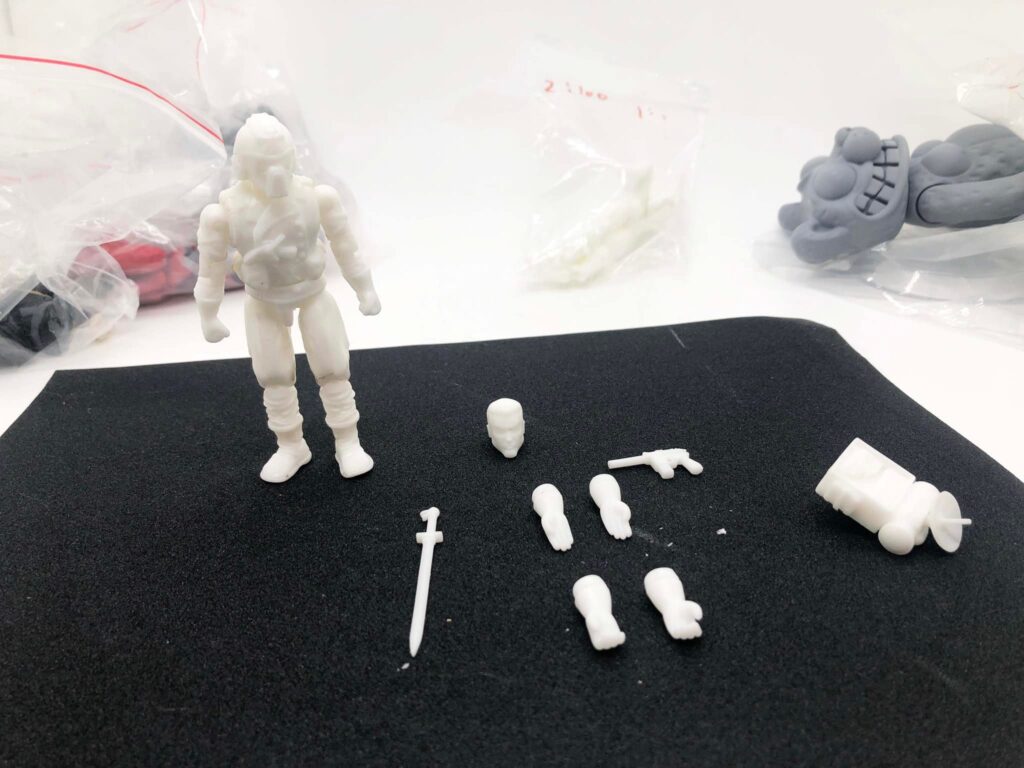

No matter how good parts are 3-d modeled there are always adjustments to be made. Good weapons and things to fit in the hand properly can be a real pain. If the handles are too tight people can’t get the handles into the figures hands, if the handles are too loose, they look like crap. Trying to explain this to someone across the planet who speaks English as a second language can be really tough. I just got these photos today and the weapons now look like they fit just right. – Jason