More reveals!

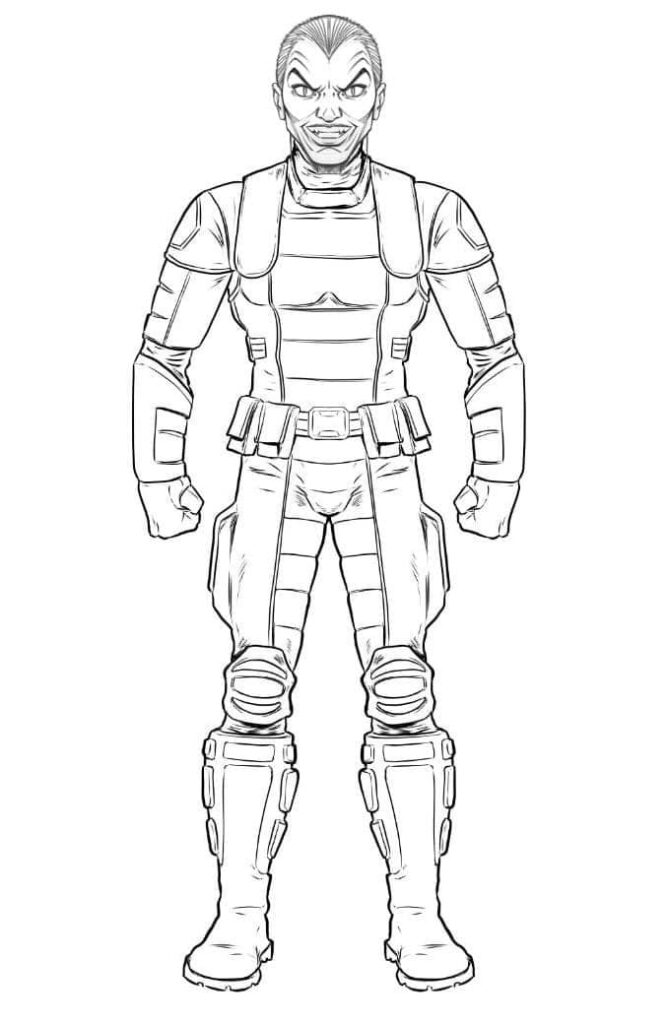

Alpha trooper, Luna trooper and Infiltraitor! – Jason

Alpha trooper, Luna trooper and Infiltraitor! – Jason

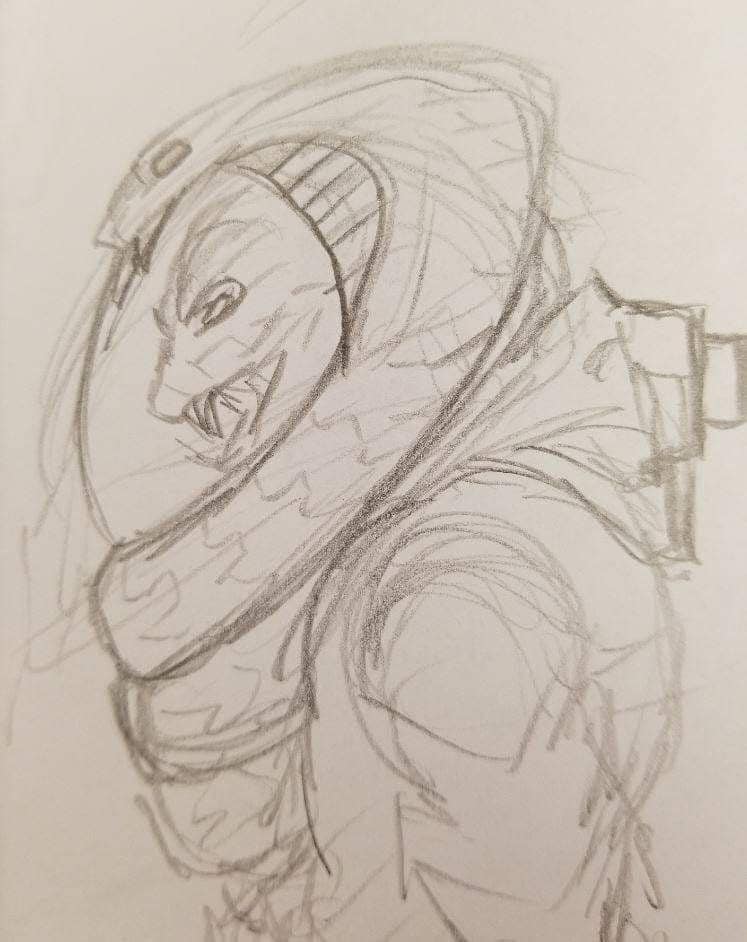

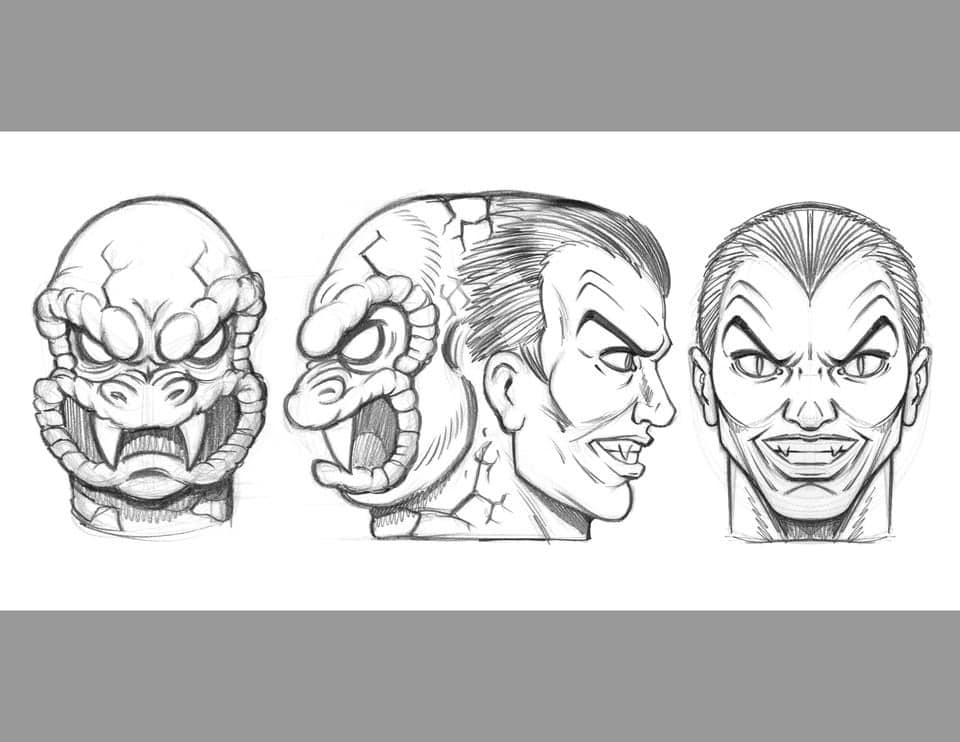

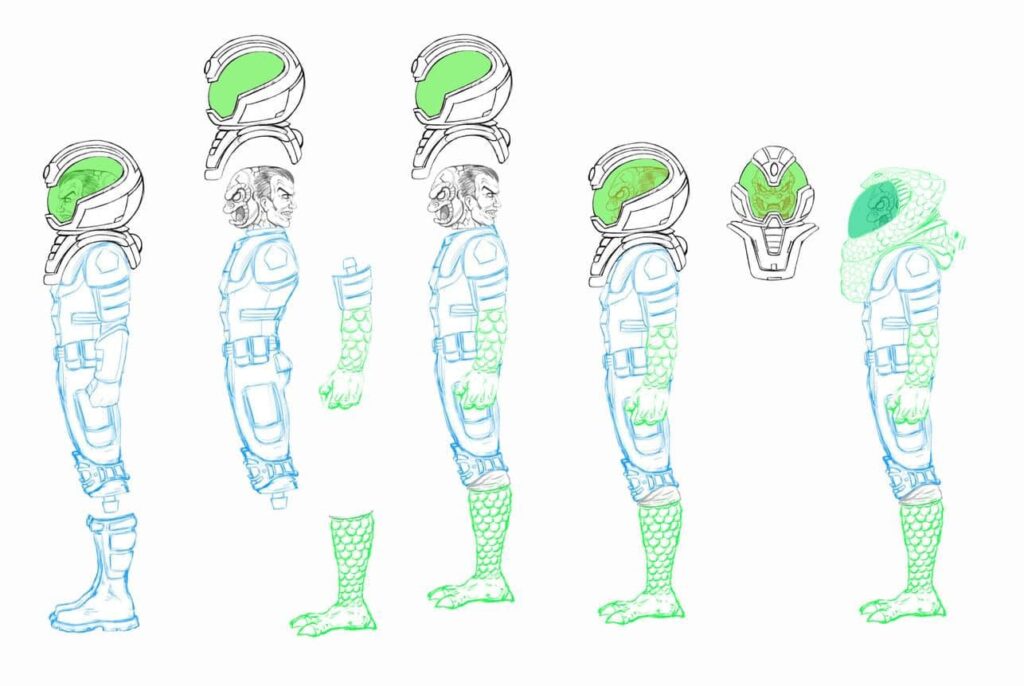

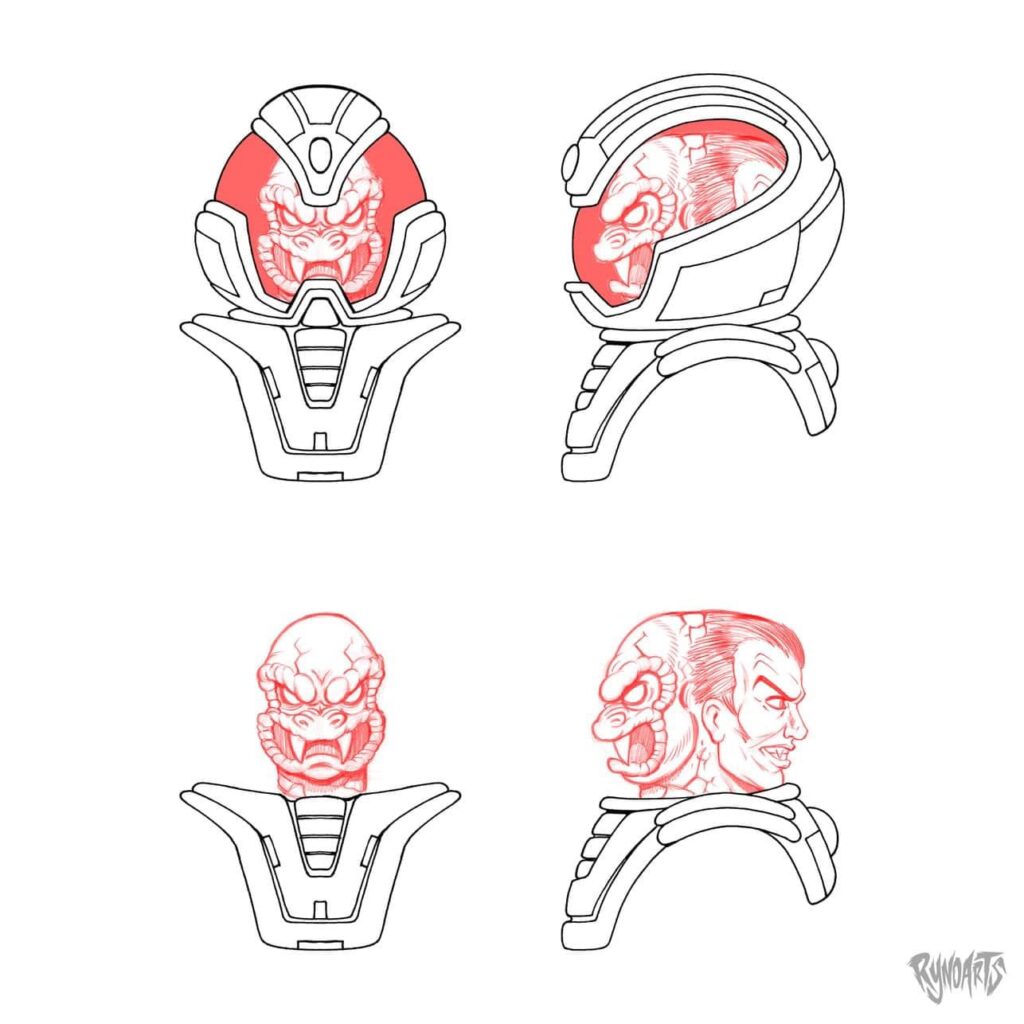

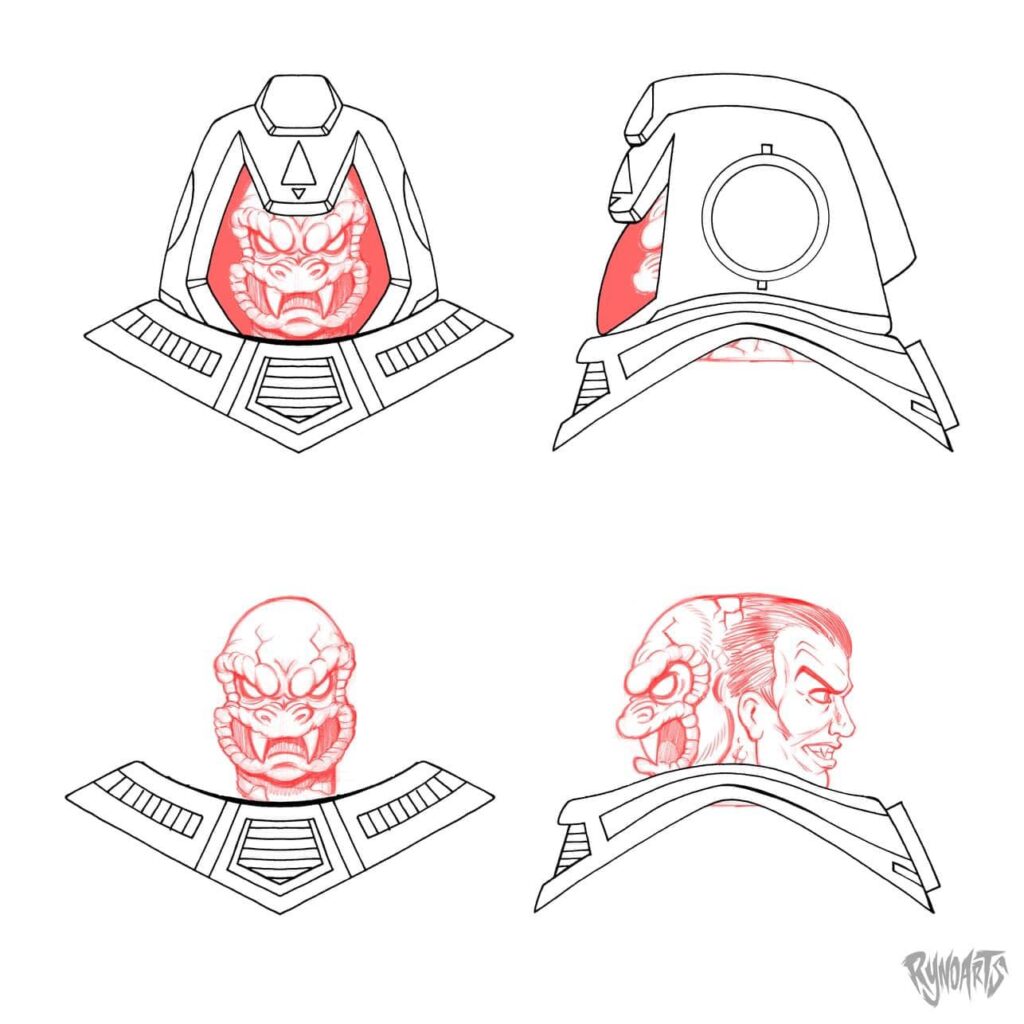

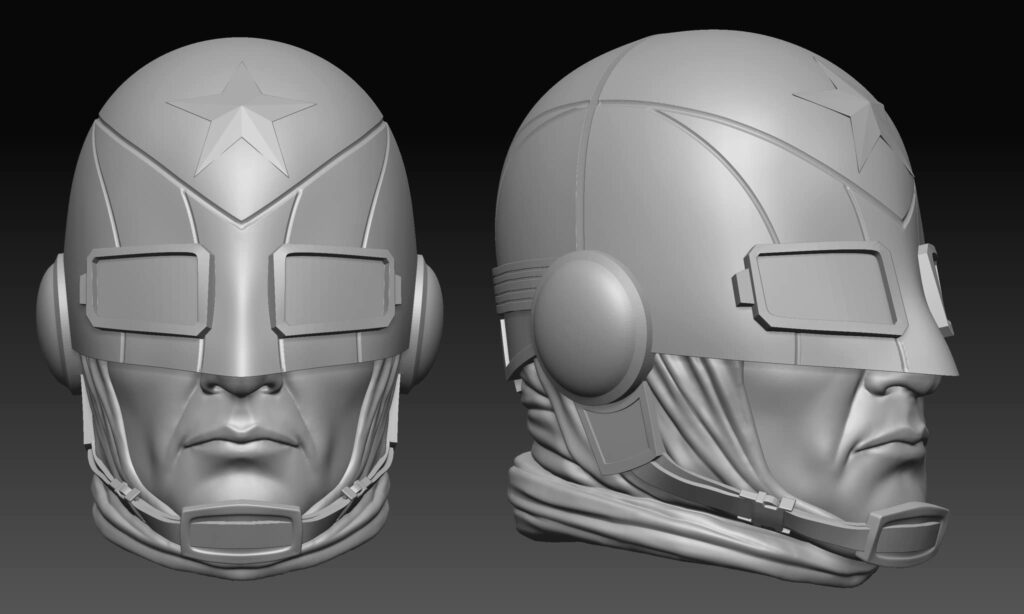

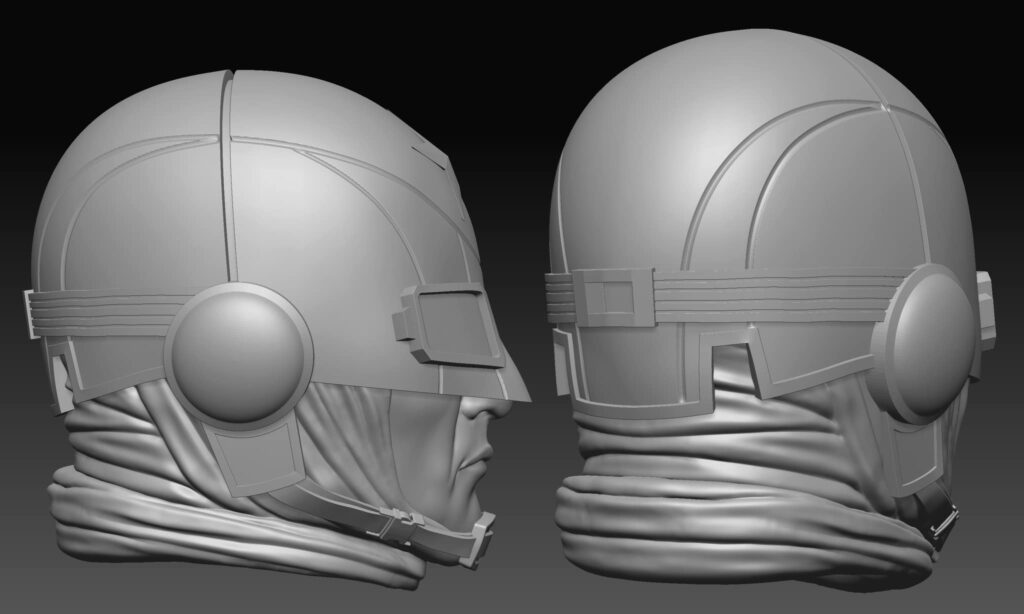

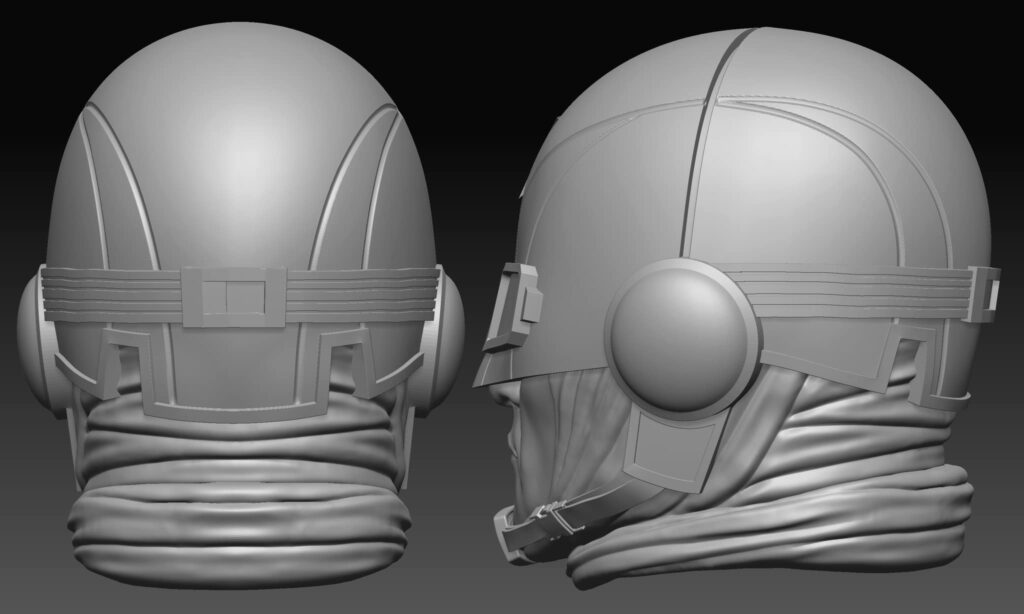

This update is for the Infiltraitor. This character was really what started the Strike Force line. The idea came about when Darren Howlett, John Kukovich and I were working on some ideas for a toyline. Kinda neat we all have toylines in production now. I really like the dual sided head concept and it really works well with the helmet design based off of John’s sketch. The infiltraitors are alien invaders that can appear like regular men. The figure comes with the parts to be a regular alpha trooper or you can convert the figure into an Infiltraitor. Works great with the Pop n Swap modular part system we use on the Strike Force Alpha line. – Jason

More final packaging examples with more to come!

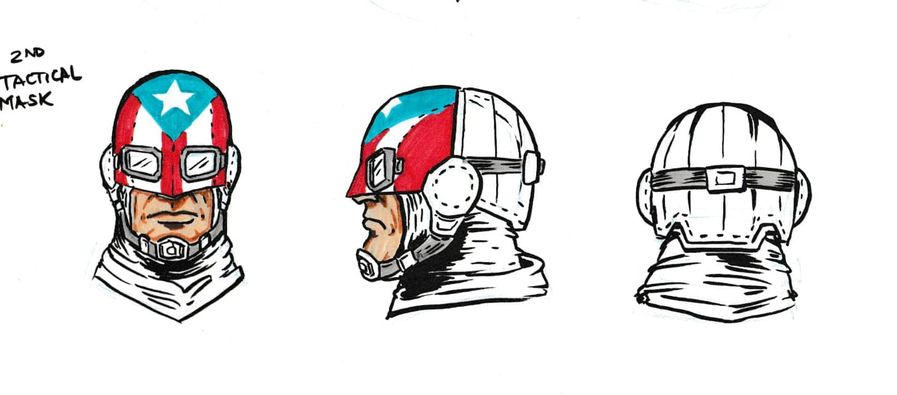

Our friend David E chose the pledge level where he could pick his own head for 10 Strike Force figures. We got the design done and David is stoked. Really cool design in my opinion. – Jason

Just got these in my inbox. The factory isn’t great with posing the figures, looks like like some arms are turned around. But these are final. Just needs the alpha trooper alternate head. This shows how the figures will be layed out. – Jason

Finally, we have some things to report. The factory has been slammed and we are doing things a little bit differently to get this order wrapped up. The order is simultaneously being worked on at three places to finish things off. Capes are being made at a clothing factory and should wrap up soon. Cards are being made at another factory. Plastic is being injected for figures and weapons; the outer package is being made while the inner trays are being figured out for each figure layout. The good news is once an order is at this stage, things move fast.

I had to create mock-ups for each figure and the parts layout. In order to layout the extra parts where they could be seen on each package we quickly ran into a problem. With the extra hands and weapons, we would either have to put them in a bag behind the figure or increase the bubble size and make an inner try for each design. That way the backpacks, guns, extra heads, and weapons would all be on display. Since we have this swappable system on the heads and hands, it was important that you can see what parts you have to play with. Also, most figures now come with a second head and those need to be on display.

The issue this caused was none of the artwork or card layouts we had would work anymore, because they’d be covered up with the bubble. So new art and layouts had to be created. Instead of artwork on the side it’s now on the top. I’m so much happier with how this card design looks. We appreciate George Vega jumping in at the last minute and getting the card art finished for us. The factory said I should have more photos tomorrow of additional packaged figures. I think from here out the updates will be more plentiful and have lots of progress photos. I will keep posting pictures every time they are available.

Since the last update I have been in contact with the factory almost nightly working through Pantone colors, tooling plans, packaging requirements, and pricing, and other questions and concerns they have. There is almost 200 individual molded parts so there are a lot of details to nail down. We’ve also been waiting for a slot in the factory’s production schedule. The factory came back this week and said the order will be finished by the end of July. I also secured the funds and paid for the order. A couple of things to note.

To expedite the order the cloth goods (capes) and packaging are starting now as well. The package will be collector friendly with the figures able to be removed.

I’ve paid extra to include an extra head with each figure. One of the heads is new and wasn’t part of the Kickstarter.

I’ve paid extra to have the paint applications upgraded on some of the figures. This also included making additional paint masks to accommodate the the upgraded paint apps. Matt did an excellent job painting samples and coming up with the paint schemes.

We are going to include stands with every order no matter how big the order is. This is just for Kickstarter backers. This doesn’t mean if you ordered 20 figured you’ll get 20 stands. There will be at least some stands in every order, exact number to be determined. I’m still negotiating a price with China on these.

If there is an opportunity to pay extra to expedite the shipping from China to the USA, I’m willing to pay that to get things in your hands quicker. We will negotiate that in the coming weeks.

The factory has agreed to document as much of this process as possible when they get to a stage where pictures can be taken. These will come more frequently in the last month or so of manufacturing. – Jason

I wanted to give everyone an update. We are moving on to the manufacturing stage. I’m going to repeat that WE ARE MOVING ON TO THE PRODUCTION STAGE! I’m excited to finally be at this point. It’s been a really long stressful process, but honestly, that’s how it goes sometimes when trying to manufacture in China. A lot of what I’m about to tell you has been experienced and talked about by many companies over the last year or so. Although I’ve made several projects in China, I’ve never experienced all of these issues. To be honest I haven’t experienced too many issues at all. When we started the project it was done with the information we had at that time. Had I known all these difficulties would arise, I would have never started the kickstarter. Now that I see these awesome figures in front of me, maybe it’s a good thing I didn’t know, because these figures need to be in collectors’ hands.

Some of the issues were the following:

Multiple people not paying for their pledges.

Issues with the parts scans from the first factory.

Conflict of interest with the first factory.

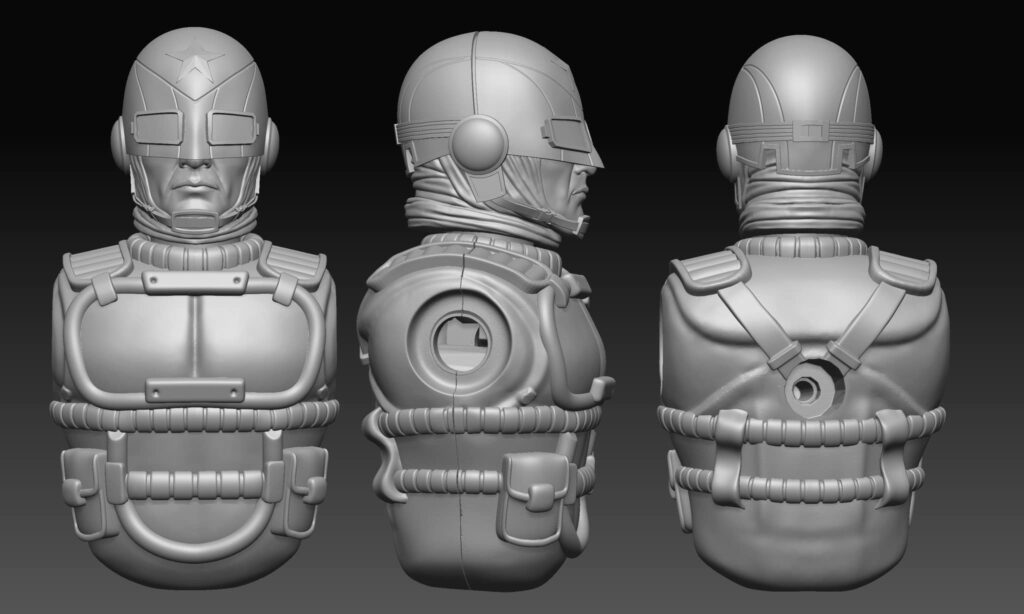

Redoing all the sculpts in digital format in record breaking time and reengineering the body since the physical scans weren’t usable and the first factory had the samples.

Moving the project to the new factory after paying for services at the first factory that weren’t usable.

Shut downs multiple times for Covid and blackouts in China

Production costs and labor costs in China increasing.

Mold factory behind schedule and not equipped to make this many molds at one time. Machinery constraints.

More covid.

Issues with engineering on some of the parts.

Running out of money (due to backer non-payment, losing funds with the first factory, re making molded parts we weren’t happy with and rising costs)

Well, you get the idea. Lots of things in the world fell apart and the timing for this project fell right in the middle of it. That being said I’m running the project and I have to take responsibility for it. Have I made mistakes along the way? Yes, I have. I’ve learned a lot through this process and there are many things I’m doing differently now on other projects. I apologize for the things I could have done better and the fact you’ve had to wait so long. I take the fact you pledged your hard-earned money to this project very seriously.

We recently got all the engineering fixes made to the mold. Some were minor, but we wanted these figures to the best we could make them. Some I think most companies wouldn’t worry about. Who cares if the figures won’t hold the weapons well and the joints break when you move them? Well, we care. These figures are Matt and I’s resume for future projects. We can’t make up lost time but we can give you the most innovative quality product we can produce.

I also sold some property I owned to ensure there was enough funds in the bank to pay for everything. In summary molds are done, funds are secured, and I’m working with the factory to get the order on the productions schedule. This should get underway in the next couple weeks. We should be able to get a tentative date when the order will be done at that time. I’m going to ask for lots of photos throughout the production process which will be a lot more exciting to look at than pictures of steel molds.

I will be at Toylanta with protypes next week (Matt is stopping by as well) I will be at the Cotswold Collectibles booth, come by and see us. – Jason

After much trial and error, emails with engineers in China and aggravation not being able to figure out what was wrong with the neck, I think we got it. The language barrier and the factory not understanding the function of the neck was hard to overcome despite sending samples. The video is from the factory. Nice little collection of toys behind them. They are remaking the necks in the mold and we are good to proceed with the order.

Watch the test video via Facebook post.